Alumni Success Story: Keiron Printing Technologies

Luck, or whatever you want to call it, is a funny thing. Bad luck can doom a startup even before it gets started, while good luck can bring the right people together to achieve great things.

Take HighTechXL alumnus Keiron Printing Technologies, for example.

The Keiron story starts with these two young guys – friends since high school – who decide to join a startup. And not just some garden variety startup with an app to find the best parties, but a deep-tech startup with laser technology from Holst Centre and TNO.

Now, the interesting thing about deep-tech is you can often do a lot of different things with one invention. Which is good and bad.

When Marco van Hoorn and Jimmy Sy-A-Chin first began the adventure of taking advanced laser printing technology – courtesy of Holst Centre and TNO’s tech transfer group – and turning it into a company, all those possibilities sent them down multiple rabbit holes. They sifted through potential applications trying to visualize how to build a company around this technology, then take it to market.

That was 2019. As they entered HighTechXL’s venture builder program, neither had even heard of LIFT, or Laser Induced Forward Transfer.

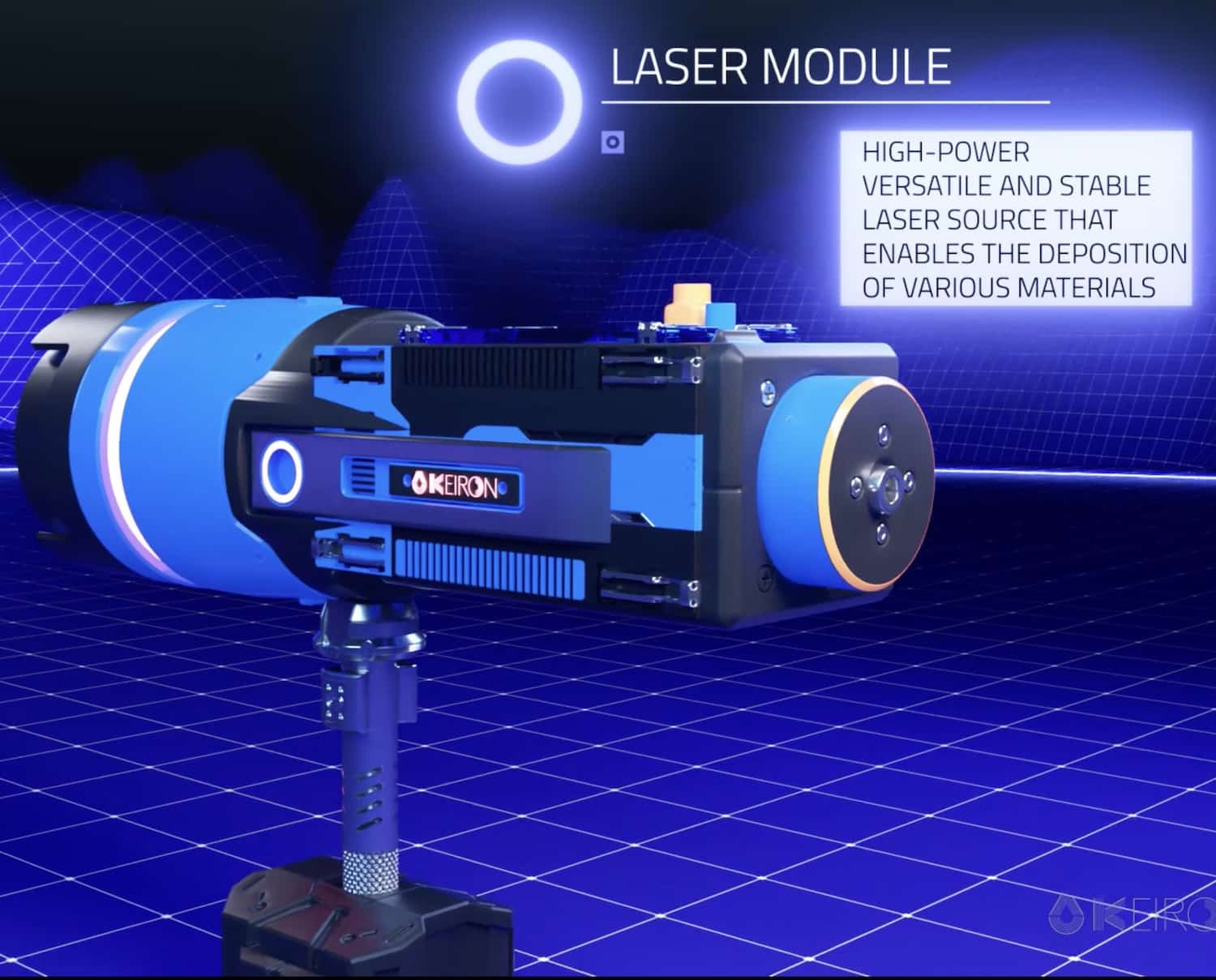

LIFT is the next wave in printing. Instead of ink and a nozzle, the process uses a laser to deposit incredibly precise layers of metal, graphene or other materials incredibly quickly. It can be used in a variety of industries, including semiconductor, packaging, consumer electronics, automotive and healthcare.

Would Keiron’s core business be lab-on-a-chip? Would they build their own machine, or would they just make money leasing access to equipment TNO already had?

“At that point, you don’t want to (restrict) yourself into one very specific niche. You kind of want to keep the options open while very much being aware of the opportunities that you have in front of you,” Marco says.

So, they did what all good founders do – they went to their potential customers for objective market research. “It was really just a matter of sending out a bunch of reach-outs and hoping that some people would like to spend some time with you to find out what it is they’re really struggling with,” Marco said.

Now, bear in mind that Jimmy and Marco were in their early 20s, playing in a game that tests the most experienced teams.

Were they too young?

No, Marco says … their inexperience made them more flexible and coachable in HighTechXL’s arduous venture building program. And with deep-tech, what does it matter? There’s no blueprint because it’s never been done before, he said.

In the beginning, all they really had was a concept, albeit a good one … one that TNO researchers had spent 10 years perfecting.

“With deep tech, you are really looking at, like, ‘Hey, I have a PowerPoint with a couple of slides showing a certain potential.’ And if you want to convey that message to the industry without having the hardware – because you don’t have money when you start – that’s a challenge,” Jimmy says.

Once you convince that first investor, you raise “a little bit of money here, little bit of money there,” he adds.

With that small amount of initial capital, you need to a prototype “and you get a little bit more, then you get a little bit more money after that. And that’s just, that’s continuously a challenge … it’s just a step-by-step approach, basically.”

As luck would have it, Marco and Jimmy were working to get Keiron up and running at the same time engineer Stefan van Waalwijk was already helping them. They just didn’t know it. Stefan was working as a researcher at TNO Holst Centre developing this new laser-enhanced printing technology before Jimmy and Marco had even joined HighTechXL. So, Stefan had a solid understanding of LIFT. In a fortuitous coincidence, TNO’s tech transfer team signed a partnership allowing HighTechXL to take the technology and build a team around it … and TNO threw in Stefan to help one day per week.

“And that’s when we meet and get together and start working together. I came in with the technology, so you have a direct link already within the team,” Stefan said. In HighTechXL’s venture-building process, Keiron initially had 12 people working at HighTechXL offices in HTC 27, people who had various levels of interest. Then the team quickly coalesced around Jimmy, Marco and Stefan as those with entrepreneurial ambitions stayed. Now Jimmy is CEO, Marco is Chief Innovation Officer and Stefan is the CTO.

All three agree that compatibility has been crucial to success.

“Yeah, it was – let’s say – a click on the fundamental personal friendship level, and that also gets you through all the (HighTechXL) program, through all the parts,” Stefan says. Sometimes team members bond around the technology.

“But to us, I think it was most important that there was also a friendship. And that helps you go through all the hard times, and through all the hard work and stay together,” Stefan says.

Staying together in deep-tech is tough since, as noted above, you’re only selling the idea until you can raise the capital to build an MVP. And that starts a process of meeting benchmarks, then raising more money while meeting new benchmarks. Three years into building Keiron, they now have a prototype LIFT machine and a lab and offices in HTC 29.

For Stefan, Jimmy and Marco there was never a “holy cow!” moment of epiphany. Instead, it was just finding puzzle pieces along the way. And they’ve learned to stop thinking in terms of what’s important to them and more about where their industry is headed.

And that’s the hard part … understanding markets and their place in them.

As they assess potential strategic partners, they’re really thinking, “Okay, how can we as a company really add value to that?” Marco says.

“And from the stand-alone equipment that we first had in mind, we were really thinking now of, let’s say, a package that you can integrate in other people’s production lines or pieces of equipment. So, it’s not that much one large Keiron machine. It’s more like a machine, which we can be an essential part of.”

He believes with LIFT, Keiron is at the beginning of a market that will take a while to mature. Just as it took inkjet printers a long time to become the industry standard.

Because people don’t know yet what they can do with it, Marco said.

The basic technology is just shining light on a thin film, then depositing what you have projected, Stefan said. “If you take on all the components, it becomes quite complex. But the basic simplicity of the process made me a believer quite quickly. The process is so simple, you have so many different things you can do with it, immediately you can see this and this and this and this.

“And that, in the end became – and still is – one of the hardest things for us.”

But the way forward is clearer.

The team is now working on additive electronics projects – 3D Electronics (PCBs), Smart Clothing (including smart watches), and more. These are feasibility projects/pilot projects. They are also moving toward a single market vertical, which is a big change from focusing on the horizontal of printed electronics, the team said.

“Our chosen vertical is PCB and semiconductor assembly – but we can’t say yet which application areas. We’re working on it,” Marco said.

All this means the size of the market is larger than they originally thought. The actual device is now a modular system that can be integrated, for instance, in the production line of, well, pretty much any manufacturing process. “That is what the market needs,” Jimmy says. “We cannot then stand there with, like, a high flag saying, ‘No, we only want to bring stand-alone machines.’

“That’s not how the deep-tech startup can survive. You need that market entry in early days, the validation to understand what customers want.

“Then you can grow.”

About HighTechXL

HighTechXL is the Netherlands’ premier deep-tech venture builder, solving societal challenges by combining groundbreaking technologies and entrepreneurship. We bring together and activate technology, talent, funding and a strong ecosystem in our unique Venture Building Program.

News